Artificial Intelligence in logistics

Artificial Intelligence often appears as a solution to optimize processes in practically all economic sectors. And also as a threat that can cause chaos. In the case of logistics, its implementation seems particularly suitable to solve, optimize and make more flexible several complex operations related to the exchange and transportation of goods. Is AI the almost magical solution for the sector? Let's take a look.

ALICE IN AI-LAND

Artificial Intelligence is “the” technology of the moment, but does it apply equally to all sectors of activity? And more importantly, does it make sense to use it across the board in all logistics organizations, or is it necessary to be clear beforehand in which operations it can be useful?

"In my opinion, it depends on the use case", answers Anike Murrenhoff, of the Fraunhofer Institute for Material Flow and Logistics IML and author and coordinator of ‘AI in Logistics’, a report in which the European technology platform ALICE (Alliance for Logistics Innovation through Collaboration in Europe) outlines its implementation in the sector and also serves as a guide for those organizations that want to start applying it.

“What has changed with the rise of AI is that we now have new tools in our toolbox that can achieve better and more complex results. Its application in the operations of logistics players is not limited to processes, as tools such as GPTs, for example, can also counteract the shortage of skilled labor and facilitate knowledge transfer and retrieval,” explains Murrenhoff.

Fernando Liesa, secretary general of ALICE, adds that in addition to the use case, value generation must be taken into account, which is linked to the degree of competence and digital maturity of the stakeholders involved in the ecosystem of each specific use case. “The value of AI depends largely on the quality of the data, its availability and the cost of aggregation versus value generation,” he says.

“The autonomization of intralogistics requires decisions to be made faster and more frequently, with a greater number of units involved (shipments, agents, etc.). This is where AI can be of help.”

Anike Murrenhoff, author of the AI in Logistics report

Why is AI a particularly suitable solution for logistics?

Several factors are contributing to the increasing degree of complexity that the logistics sector is experiencing.

- “One is the desire for greater individualization among end customers, which has resulted in a significant increase in e-commerce and, consequently, a reduction in the number of large shipments,” notes Murrenhoff.

The author also cites the need to transform logistics toward systems that are more flexible, more scalable and adaptable.

- “This can be seen in the autonomization of intralogistics, which in turn requires decisions to be made faster and more frequently, with a greater number of units involved (shipments, agents, etc.). This is where AI can be of help,” lists the author of the report on AI in the logistics sector.

In addition to this complexity, Liesa mentions the availability of data through IoT sensors, devices, etc., and technological capabilities that can be better leveraged, e.g., supercomputing and data spaces.

- “All these ingredients create a great opportunity in the field of logistics to increase efficiency, support decision making and the creation of automated processes,” assesses the ALICE secretary general.

On the management of this data, the ALICE Secretary General applauds the creation and drafting of international regulations and standards that create a level playing field and ensure the existence of a regulated market that allows solutions to be developed and adopted.

- “Dispersed regulation would create regulatory silos and then barriers to the adoption of solutions in regions with different rules and regulations. That said, there are markets that protect individual data more and others less, which will create debate and different positions,” Liesa believes.

Liesa believes that leadership in standardization should be provided by the industry, specifically by platforms such as the International Data Space Association.

- “As for regulation, and at the European level, it should be the competence of the European Union and not of each country, as the EU would have a higher success rate in global forums related to AI regulation,” he expounds.

Specific operations that AI can improve

Among the most visible benefits of applying AI in logistics are:

- Demand forecasting: AI can analyze large amounts of data to predict demand more accurately, helping companies manage inventory levels more efficiently.

- Route optimization: Algorithms can find the most efficient routes for ships, planes and trucks, taking into account traffic, port congestion, warfare, weather and other variables to reduce fuel consumption and suggest mitigation strategies.

- AI can analyze customer behavior to provide personalized product recommendations and shipping options. AI-based customer service bots can handle queries and provide real-time assistance, enhancing the customer experience.

- AI can provide real-time visibility of shipment status, streamline port operations, predict vessel arrival times to enable better tracking and coordination throughout the supply chain. This improves reliability and customer satisfaction.

- AI will optimize routes and improve fuel efficiency, reducing the carbon footprint of logistics operations. In addition, better inventory management will minimize waste.

ALICE experts explain that the AI applications that are being used most rapidly in logistics are hardware-related, such as robotics, machine vision or natural language processing for documents.

“Since the rapid rise of generative AI, applications of large linguistic models (LLMs) for augmented retrieval generation (RAG) have seen an increase across different sectors of the logistics industry, with no differences between subsectors,” shares Murrenhoff.

The Port of Barcelona already uses AI in the management of MARPOL waste and in the verification of cargo on ferries using LIDAR sensors. It is a solution that generates point clouds representing physical objects, processes them and segments the information to distinguish between different types of waste and cargo.

AI solutions for ports

The ALICE whitepaper includes examples of different AI applications that contribute to solving specific problems in each of the application ports.

Murrenhoff highlights four main uses:

- Load handling automation

AI is used to control cranes, forklifts and automated transport vehicles. “Especially through computer vision applications, for example, for container identification,” she details.

- Forecasting and optimization

AI algorithms analyze data to predict freight traffic and improve resource planning. “This includes predicting vessel arrival times, allocating storage space, and managing material flows in the loading and unloading processes,” she stresses.

- Maintenance and repair

AI supports predictive maintenance by monitoring machines and equipment at ports, predicting potential failures and minimizing unplanned downtime.

- Real-time environment monitoring

AI can help to obtain, from different sensors, useful information that is currently not possible to collect. This information would allow decisions to be made more quickly and with greater knowledge of the situation in real time.

Liesa, for his part, defines these applications as “incipient,” and believes that it will take a couple of years to be able to define the most common use of AI in ports. “It will probably depend on the type of port, its size and the type of cargo, as well as the industrial sector that the port feeds or feeds most. It is unlikely that you will come up with solutions that will fit all types of ports,” he opines.

Port AI use cases

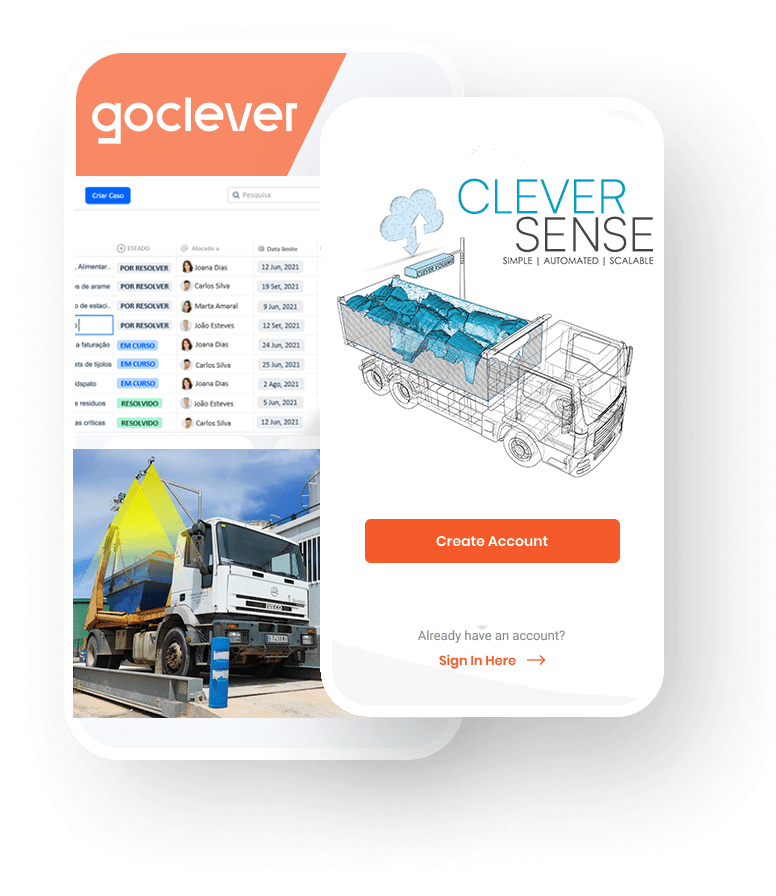

- GoClever's Clever Sense solution at the Port de Barcelona

Using LIDAR sensors that generate point clouds representing physical objects, such as waste and cargo containers, which it then processes through algorithms, Clever Sense is able to segment information to distinguish between different types of waste and cargo, even in varying environmental conditions.

This solution optimizes two critical areas: waste quantification (MARPOL) and cargo verification at ferry terminals.

Detecting the presence or absence of seals on containers arriving at a port is of vital importance to the port operator, as it validates the integrity of the contents. Currently, this checking process is manual, with the significant security risk involved.

This solution consists of a CCTV camera facing the front of the container. It provides real-time images to an object detection algorithm that extracts relevant information about the containers while the crane is loading or unloading them.

Awake.AI is collaborating with the port of Antwerp for the realization of a safe environment for the berthing of autonomous barges. In addition, they also want to manage the loading and unloading of these barges and ensure a safe navigation environment.

- Captain AI a the port of Rotterdam

To navigate safely, shippers must be aware of vessels in their vicinity. Advanced radar detection prevents collisions and warns mariners of potential hazards.

The Radar Tracker uses Deep Learning techniques by collecting and tagging data using radars, cameras, GPS, Octance and AIS already installed on most vessels.

- PORTXCHANGE at the port of Algeciras

PortXchange is a collaborative digital platform between shipping lines, port authorities and terminals to optimally plan, execute and monitor in real time all activities that occur during a port call.

It combines advanced tools such as cloud computing, machine learning and APIs to display planning updates that allow a vessel to optimize its speed and reduce unnecessary emissions.

- Empty Equipment Repository Management (E2RM) in Valencia

The management of the fleet of empty containers is complex to optimize for various reasons, including the level of operational uncertainty involved in their reception and delivery.

The E2RM system applies machine learning algorithms to generate reliable predictions of these receiving and delivery operations and will autonomously manage predictive models to quickly adapt to changing patterns of container supply, demand and traffic.