More than a hundred projects studying the feasibility of using zero-emission fuels are underway, the majority in Europe and Asia. (GettyImages/PierNext)

More than a hundred projects studying the feasibility of using zero-emission fuels are underway, the majority in Europe and Asia. (GettyImages/PierNext)

Carbon-neutral fuels in maritime transport: a long journey with no return

Maritime transport moves towards the goal of sustainability on various fronts and more than a hundred projects are already exploring the viability of designing low carbon ships. Vessels of the new Grimaldi Green 5th Generation class which use lithium batteries that charge during navigation have docked at the Port of Barcelona, making a huge step to achieve zero-emission in port. Meanwhile, in Norway, the world's first zero-emission ship is currently being designed.

More than a hundred projects studying the feasibility of using zero-emission fuels are underway, the majority in Europe and Asia. (GettyImages/PierNext)

More than a hundred projects studying the feasibility of using zero-emission fuels are underway, the majority in Europe and Asia. (GettyImages/PierNext)

How can vessels support the fight against climate change?

The roadmap to zero emission from international shipping was the star topic of the meeting that the Marine Environment Protection Committee held in 2018. In line with the Paris Agreements, the Member States of the International Maritime Organization showed their commitment to reduce the annual CO2 emissions by at least 50% by 2050 compared to 2008 levels.

The preferred ongoing projects: hydrogen, ammonia, methanol / ethanol

The report 'New Mapping of Zero Emission Pilots and Demonstration Projects' published by the Global Maritime Forum in March 2021, includes 106 projects focused on naval, production, supply and refueling technologies that use, in this order, hydrogen, ammonia , methanol / ethanol, electric batteries, wind, biofuels and liquefied biogas, most of which are being developed in Europe (71) and in Asia (31).

Based on the report's findings, two trends can be established towards achieving more environmentally friendly cargo ships. In larger vessels, projects developed with ammonia and methanol / ethanol have experienced a higher increase, while in smaller vessels hydrogen stands out above the rest.

What are the differences between carbon-neutral fuels?

The study 'Zero-Emission Vessels 2030', published by Lloyd's Register and University Maritime Advisory Services (UMAS), raises an interesting question on the green ship concept: Which zero-emission technologies are most viable to power vessels with the same capacity as ships that use fossil fuels? ? The answer does not depend on a single factor, since it has economic (costs, profitability), production (where these fuels are obtained) implications and needs to consider other elements such as storage, handling and transportation.

The results of the study conclude that biofuels are the most attractive zero-emission solution, since they outperform the others in economic terms. However, they present two key challenges: sustainability and the availability of natural resources for their production. Its production for maritime transport collides with other social objectives, such as food production, which could result in a finite supply that would lead to a rise in prices, and reduce its competitiveness.

Electric power from batteries is not, currently, a competitive technology and requires a significant additional evolution in terms of performance and cost reduction. The focus changes when it is used as an assistive technology.

Finally, hydrogen and ammonia are presented as intermediate solutions, although the study indicates that it will depend on how the technology and raw materials associated with their production and storage mature and how it will impact the balance between their respective prices as fuels and onboard storage costs.

In larger vessels, projects developed with ammonia and methanol /ethanol have increased, while in smaller vessels hydrogen stands out above the rest

Grimaldi GG5G: lithium batteries and solar panels

February 5, 2021 can represent a before and after on the road to achieving zero emissions in ports. That day the vessel Eco Barcelona, one of the 12 hybrid ro-ro ships of the new Grimaldi Green 5th Generation (GG5G) class, which combines fossil fuels and electricity, docked in the Port of Barcelona.

The characteristic that makes it unique in the world is that its lithium batteries are recharged during navigation thanks to its generator shaft and its 350 square meters of solar panels, and therefore, it does not generate any type of emission while it is docked in the port, since it uses the electricity stored during navigation.

In addition, its cargo capacity doubles that of the company's larger vessels and consumes the same amount of fuel at the same speed, thus doubling its efficiency in terms of emissions per ton transported.

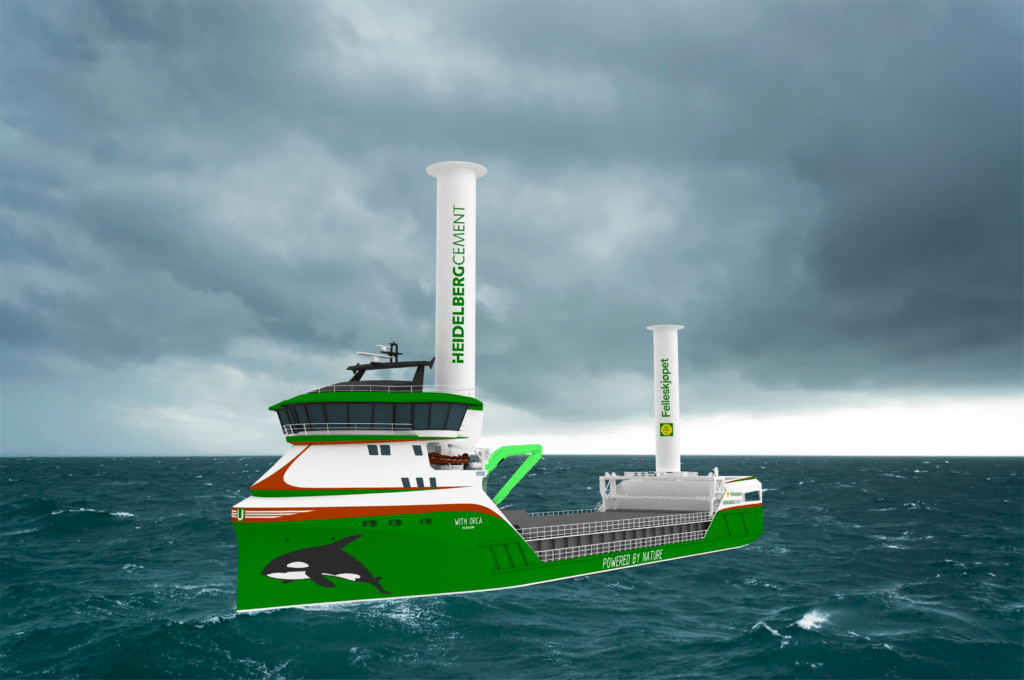

“With Orca” – Powered by Nature: hydrogen and wind

The self-proclaimed world's first zero-emission cargo ship, named “With Orca” - Powered by Nature which expects to start sailing in 2024, is an initiative of the German cement manufacturer HeidelbergCement and the Norwegian agricultural products distributor Felleskjøpet Agri. It will be powered by hydrogen and the wind from the North Sea.

Both companies have a 15-year agreement to operate the vessel that will transport aggregates from western Norway to eastern Norway, where the HeidelbergCement Norway plant is located and, upon their return, cereals from Felleskjøpet AGRI.

The vessel is currently being designed by Norwegian shipowner Egil Ulvan Rederi and Norwegian Ship Design Company, a Norwegian ship design and engineering company. Hans Kristian Dyrli, project development manager at Norwegian Ship Design Company, explains that they are currently in discussions with the Norwegian Maritime Authority with the aim of receiving an “approval in principle” for the ship's concept.

“In this case, hydrogen’s high flammability required us, for safety reasons, to rethink the basic vessel design, moving the superstructure with living quarters to the bow and concentrating all hydrogen installations in the stern, despite the fact that the location is not yet decided for this vessel,” he explains.

Dyrli points out that due to the fact that storage and/or transportation of large quantities of hydrogen may not be approved by the Authorities or port authorities in many ports, they have opted to add two large rotor sails to propel the 88-meter-long vessel using wind power.

“We believe energy costs will increase in the future and direct onboard use of wind energy will play an important part in achieving zero-emission sea transport. The vessel will be designed for optimal efficiency when sailing using wind. Rotorsails are the most suitable type of sail, as they have a little footprint relative to the propulsion force they generate,” he justifies.

Although many designed features cannot not currently be disclosed, he shares that hydrogen adds some complexities. For example, high flammability requires special design which suppliers will have to face, and many have limited or no maritime experience at all.

“Ship design is an iterative process, and adding complexity such as hydrogen and wind propulsion, means that we are likely to spend more time in the “design spiral” and that we may need a few extra rounds in it compared to a conventional ship. A systematic design approach is even more important with added complexity,” he concludes.

Despite these initiatives, the challenge of reaching carbon-neutral emissions by 2050 is perhaps too ambitious, as achieving this goal would require an unprecedented transformation in fuel production, transportation and use. To achieve this in thirty years time, global annual investment in clean energy will need to triple by 2030 to $4 billion.

Even so, ships can contribute to the fight against the impact of climate change by developing and accelerating clean technologies that scare away bad omens.