These CCUS technologies, as outlined by the EU in its Zero Net Emissions Industry Act, are starting to be implemented in the maritime sector. (Getty Images)

These CCUS technologies, as outlined by the EU in its Zero Net Emissions Industry Act, are starting to be implemented in the maritime sector. (Getty Images)

Capturing carbon on board, a new way to decarbonise shipping

Onboard Carbon Capture (OCC) technology is designed to enable ships to capture the CO2 they emit during their voyages, thus preventing CO2 from further warming the atmosphere and accelerating climate change. Several projects are already testing OCC technology on different vessels to test its scope and take a further step towards the decarbonisation of the maritime sector.

These CCUS technologies, as outlined by the EU in its Zero Net Emissions Industry Act, are starting to be implemented in the maritime sector. (Getty Images)

These CCUS technologies, as outlined by the EU in its Zero Net Emissions Industry Act, are starting to be implemented in the maritime sector. (Getty Images)

Decarbonisation poses the great challenge of transforming our production and consumption system to reduce greenhouse gas emissions. But to prevent them from continuing to warm our atmosphere and accelerate climate change, we must not only reduce - or, ideally, eliminate - our emissions: we also need to capture the carbon dioxide (CO2) we have already emitted over the past decades.

This can be done by harnessing natural processes and also through carbon capture, use and storage (CCUS) technologies.

The EU has included these CCUS technologies as main tools to reduce emissions and is committed to their development. In Spain, as Mariano Marzo, director of the Chair in "Energy Transition University of Barcelona-Repsol Foundation'' and member of the Advisory Council of the Spanish Energy Club, explained in an article in the newspaper La Vanguardia on 13 June, "Spain can and should play a key role because it has an industry with the technological capacity to build CO2 capture and storage facilities and become a relevant player in the sector (...) A first step would be to incorporate CCS technologies into the Spanish energy sector. ...) A first step would be to incorporate CCUS into the National Integrated Energy and Climate Plan (PNIEC), which is currently under review."

These CCUS technologies, as pointed out by the EU in its law on zero net emissions industry, are mainly aimed at reducing the environmental impact of sectors such as energy or industry, but are also beginning to have a presence in the maritime sector.

OCC (Onboard Carbon Capture): technology in development

As their name suggests, OCCs are designed to capture CO2 from greenhouse gas emissions generated on board. Currently, they can be used with fossil fuels, e-fuel and derivatives from organic carbon-containing sources. This is why this technology is considered to be a future-proof technology.

"Shipboard carbon capture systems could play an important role in reducing emissions intensity in the medium term," explains Thomas McKenney, head of Ship Design at the Mærsk Mc-Kinney Møller Center for Zero Carbon Shipping, an independent, non-profit research and development centre that seeks to accelerate the energy transition in the maritime industry.

"Due to potential limitations in the availability of alternative fuels and uncertainties in pricing, technology-based solutions such as carbon capture are being developed in parallel with alternative fuels," he adds.

According to organisations such as the International Energy Agency (IEA), all CCUS technologies are expected to be key to meeting the Paris Agreement target. In other words, global temperatures should not rise more than 1.5 degrees Celsius above pre-industrial averages (1850-1900). But for this to happen, implementation must be stepped up.

Onboard Carbon Capture (OCC) technologies in operation:

How does OCC technology work?

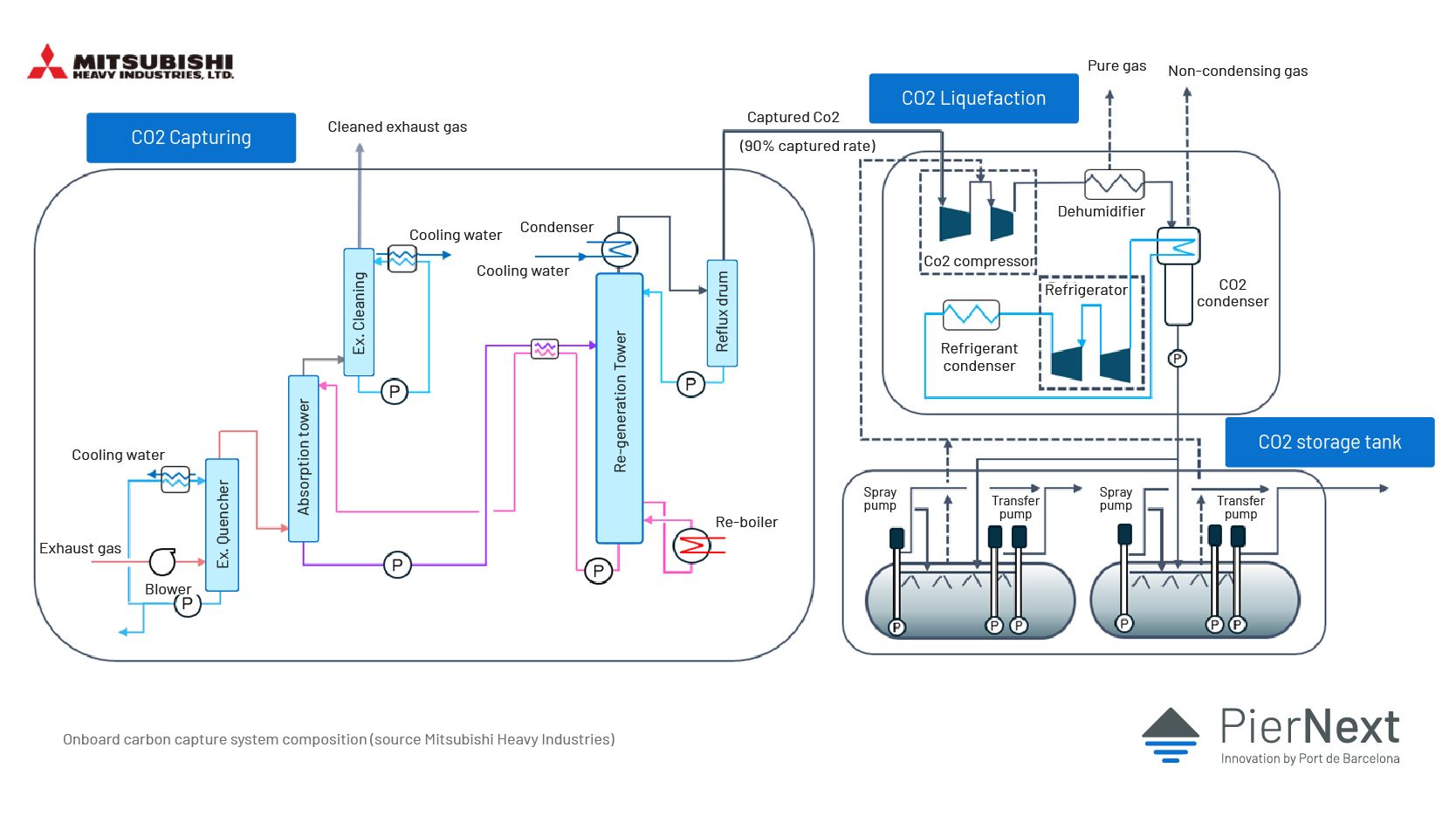

Currently available technology allows for the separation and capture of gases both upstream and downstream of combustion. When it comes to post-combustion capture, engine exhaust gas is used to capture CO2. And, according to McKenney, there are several different options to achieve this that can be used on board ships.

"Currently, there are different technologies for capturing carbon from ships' exhaust gases, as well as various storage systems," McKenney explains. "Amine afterburner absorption and liquid CO2 storage is one of the most advanced. This system is based on a capture unit, a liquefaction unit and a storage tank.”

The reduction potential of these systems can reach 75 or even 80% of tank-to-wake emissions (those resulting from the use of the fuel once it is already in the tank).

"However, although the emission reduction potential is high, the costs of capturing this CO2 are currently high," adds the head of Ship Design at the Fonden Mærsk Mc-Kinney Møller Center for Zero Carbon Shipping.

According to the study 'The role of onboard carbon capture in maritime decarbonization', in which the organisation analyses cases in which a total or partial installation of OCC technology was carried out on large ships, the cost of reduction can range between 220 and 290 dollars per tonne of CO2. These figures correspond to one of the cases studied, in which a carbon capture system was installed on board an oil tanker.

Onboard carbon capture system:

OCCs are designed to capture CO2 from greenhouse gas emissions generated on board ships and can be used with fossil fuels, e-fuel and derivatives from organic carbon-containing sources

OCC examples: HMM, Sener, SHI and Mitsubishi

Currently, several companies have initiated projects to incorporate this technology into their vessels.

One example is Hyundai Merchant Marine (HMM), which has recently announced that it will start a series of field trials of an OCC system for container ships with Samsung Heavy Industries (SHI) and Panasia. The company made the announcement after a study revealed that installing the system would not hinder ship operations.

In Spain, the technology and engineering group Sener has also recently presented a project to create a fuel supply vessel that will have a carbon capture system on board. According to Sener, this system is prepared to store CO2 captures from the vessel itself and others in its vicinity, which will contribute to reducing emissions in the area of operation.

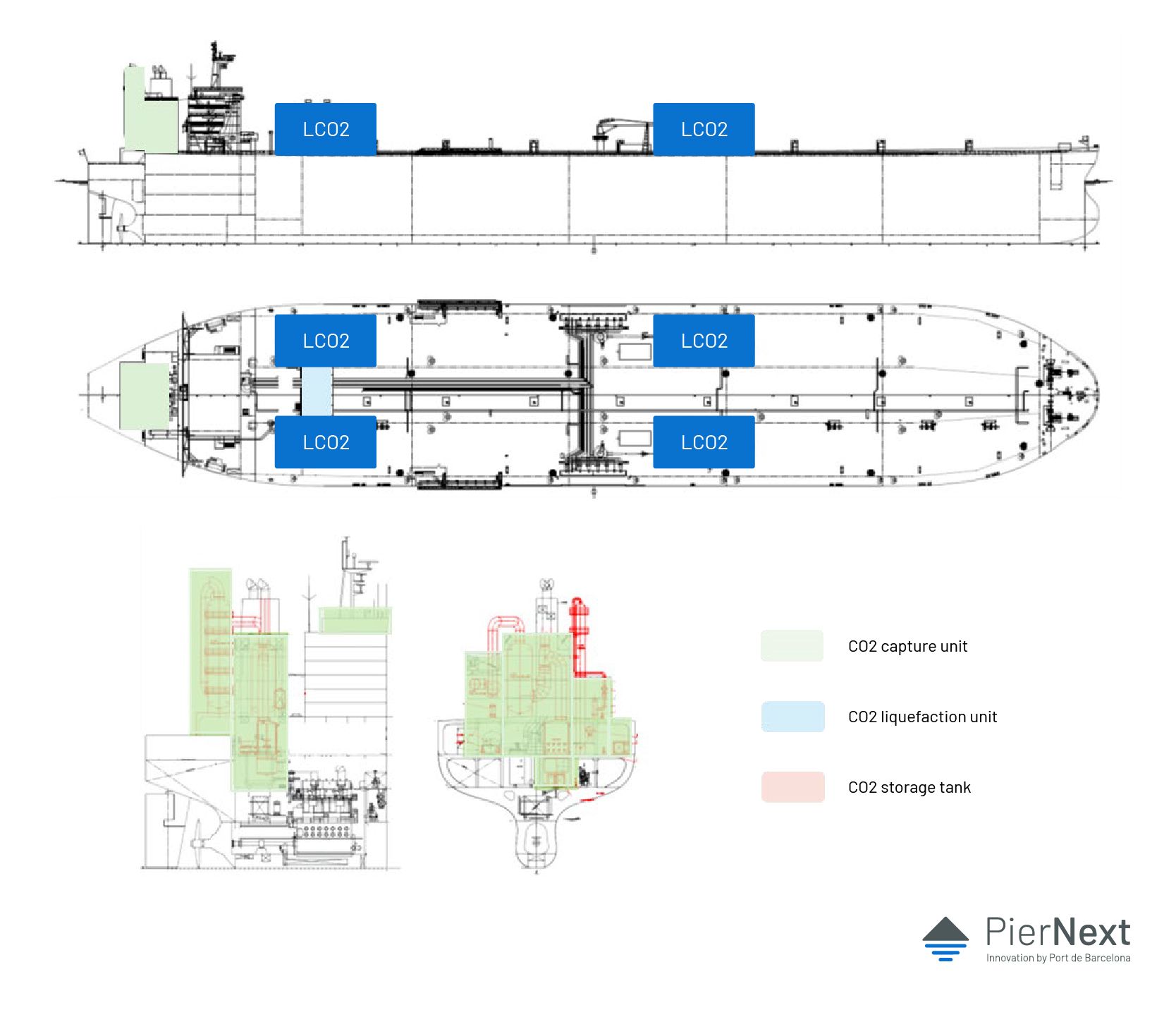

On the other side of the globe, in Japan, Mitsubishi Shipbuilding Co., Ltd. equipped a ship with a small-scale CO2 capture plant that allowed it to separate and capture CO2 from exhaust gases, as part of its Carbon Capture on the Ocean (CC-Ocean) project. Tests served to measure the efficiency of the system and showed that the CO2 captured was over 99.9% pure.

In this case, the plant installed on the ship was based on a land-based system adapted for use on board. The project was awarded the Marine Engineering of the Year 2021 (Doko Memorial Award) by the Japan Institute of Marine Engineering (JIME).

The future of on-board carbon sequestration

Currently, the applicability of OCC technologies depends on a number of factors, including the costs of developing the technology and the creation of a regulatory framework. "The development of carbon capture technology is advanced, but there are significant risks that need to be mitigated before large-scale commercial application," McKenney explains.

The main ones are additional demand for on-board power, potential loss of cargo, delay in developing a regulatory framework or markets to obtain credit for CO2 reduction, and a delay in the development of shore-based infrastructure. More analysis is needed to maximise emissions reductions and minimise costs, as well as to develop business models that allow for the utilisation and storage of carbon captured on board ships," he adds.

In fact, the lack of CO2 collection logistics in ports and the potential loss of cargo space due to the installation of the capture system and the additional tank to store CO2 is one of the main handicaps pointed out by Dani Ruiz, environmental consultant at the Port of Barcelona, an expert in alternative fuels.

Ruiz points specifically to a study by DNV which indicates that the regulation for the use of CCS on board would be available sooner, around 2024, than the technology itself, given that it does not have any complications from the point of view of safety.

And according to forecasts by Fonden Mærsk Mc-Kinney Møller Center for Zero Carbon Shipping, several current liquefied CO2 transport projects that also include liquefaction and storage systems are expected to be on board ships by 2025.

To find out more:

The Role of Onboard Carbon Capture in Maritime Decarbonization

International Energy Agency (IEA) About CCUS

HMM tests carbon capture system for containerships (Port Technology)

Reducing emissions from the shipping sector (European Comission)