Challenges and opportunities for offshore wind energy

The oceans contain a great untapped energy resource. Offshore wind platforms, both those located on fixed and floating platforms, will make it possible to take advantage of this resource. At the same time, they can turn ports into hubs of innovation and development essential for the construction and maintenance of their structures.

The potential of offshore platforms

Offshore wind is a clean, renewable and unlimited source of energy. As such, it is presented as an alternative to fossil fuels and as an important opportunity to advance decarbonization and address climate and environmental challenges.

"The oceans contain the largest energy resource on the planet. According to the World Bank, the global technical potential for offshore wind energy is estimated at 71 TW, 70% of which is in deep water, suitable for floating wind power. To put this in perspective, just 1% of the global offshore wind energy resource could generate enough electricity to meet current global demand”, points out Alex Raventos, CEO and co-founder of X1Wind, a company that develops innovative systems for the floating offshore energy sector.

Offshore wind farms harness the power of the wind produced at sea to generate electricity, which is then driven onshore. Currently, commercial offshore wind farms are mostly based on wind turbines on fixed foundations. However, the development of floating platforms promises major changes in the near future.

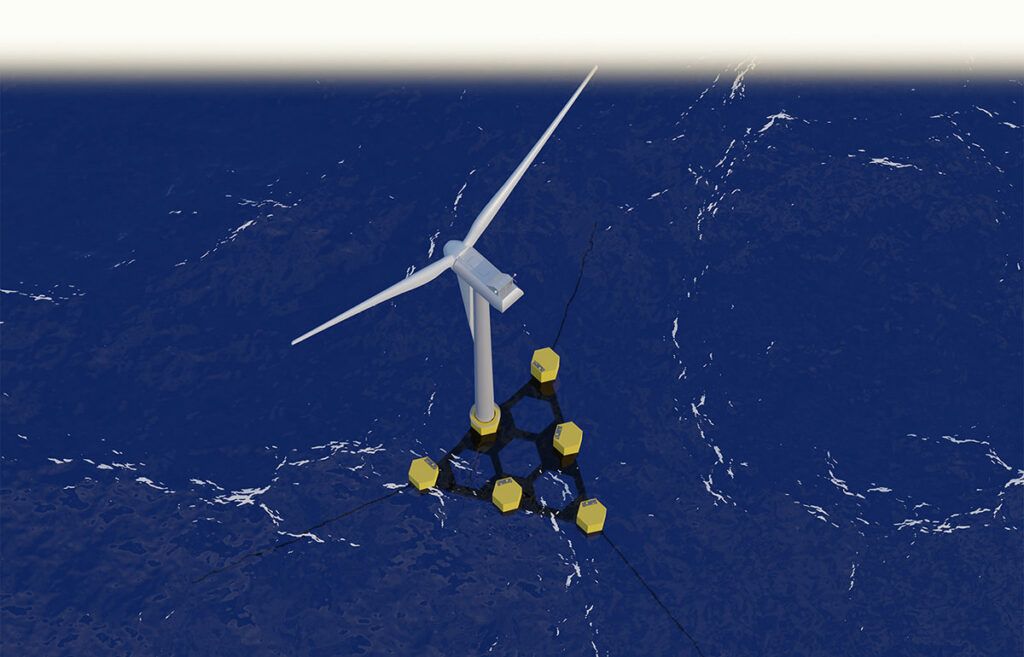

Floating platforms (also known as FOWP, for Flotating Offshore Wind Platform) are concrete, steel or hybrid structures on which wind turbines that capture wind energy are installed. These platforms anchor and provide buoyancy and stability to the wind turbine.

Unlike platforms with fixed foundations, these can be located in water depths of more than 60 meters to take advantage of the wind power produced offshore (where, with some exceptions, it is more intense and constant than on the coast or inland). The wind moves the blades of the wind turbine, which converts the kinetic energy into electricity. This electricity is then carried to the coast by submarine cables.

“A floating wind turbine works just like other wind turbines, but instead of having its tower fixed to the ground, it sits on a platform with mooring lines that connect to anchors on the seabed,” explains Raventos. “These mooring lines prevent the platform from drifting and give it the stability it needs to survive 25 to 30 years, with technology and design standards that come from the oil&gas sector with many decades of experience in the most extreme conditions,” he adds.

Floating platforms make it possible to take advantage of the great wind potential found in deep waters, those deeper than 60 meters. This is the continuation of an advance that began a few decades ago, when the first offshore platforms were erected, initially in shallow, shallow waters.

Floating offshore wind farms

Floating offshore wind farms have many advantages. First of all, by being located in deeper waters, they increase the available space and make it possible to develop larger farms in places where there are better resources. “In addition, the possibility of having ships for transport and installation allows us to use higher power turbines per unit,” explains X1Wind's CEO.

“On the other hand, offshore wind farms reduce environmental and visual impact and allow for greater compatibility with other uses of space compared to their onshore counterparts,” he says. Added to this, floating platforms add ease of movement in some operations. They can be towed to port if necessary and, at the end of their useful life, their dismantling is simpler. “This makes it possible to leave the environment as it was before installation,” adds X1Wind's CEO.

Other initiatives point in the same direction. Sener Renewable Investments and Nervión-Naval Offshore, for example, have created HiveWind, a semi-submersible platform designed as a floating steel foundation that can support wind turbines of more than 15 megawatts.

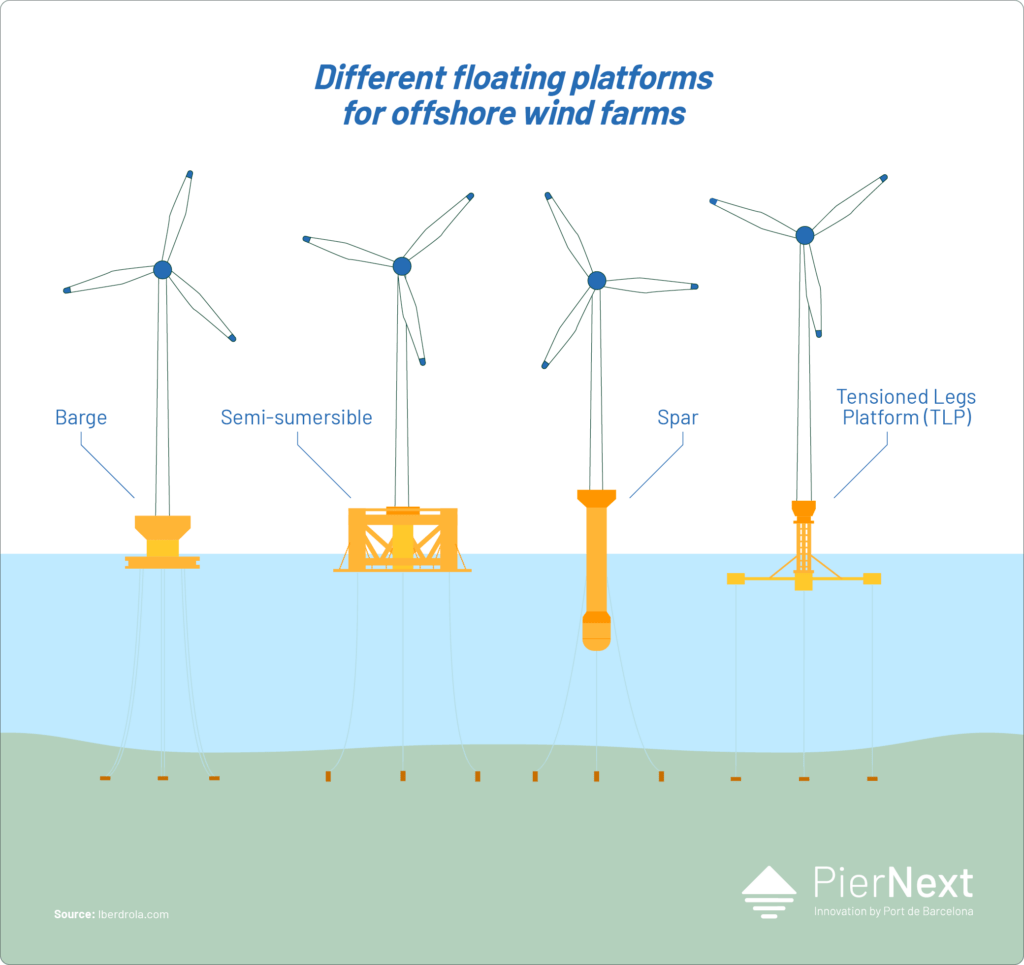

As can be seen, platforms can be of various types, depending on many factors, geographic, technical and economic:

- Barge. Platform similar to a boat, with a lot of contact with the water, which gives it stability.

- Semi-submersible. The objective is to reduce the surface area exposed to water. The volumes that provide buoyancy are several vertical cylinders connected by beams and suspenders.

- Spar. In this type, most of the weight is placed at the lowest possible point, with a high-mass cylinder at the opposite end from where the turbine is installed to maintain verticality.

- Tensioned Legs Platform (TLP). One of the newest platform types, which seeks to reduce the dimensions and, with it, the manufacturing cost. The platform does not actually float once the turbine is installed on it.

Figures, challenges and expectations

The past few years have been good years for the offshore wind industry. Over 2022 year, 8.8 GW of new offshore wind power was added to the grid, bringing total global capacity to 64.3 GW. These are data from the ‘Global Offshore Wind Report 2023’, by the Global Wind Energy Council (GWEC).

The entity also foresees an increase in capacity of 380 GW over the next few years, which would result in a total figure of 447 GW by the end of 2030. There are currently plans to increase capacity on all continents except Antarctica, although most of the projects will be developed in the Asia Pacific region.

The situation is different for floating wind power systems, which still need a boost to make commercialization a reality. According to the GWEC report, the global floating offshore wind portfolio doubled in the last 12 months and different projects are expected to be built in the coming years, which would allow commercialization by 2030. In this case, Europe is leading the race.

“Currently, the floating wind industry faces several factors that hinder growth: a lower technological maturity than other technologies (such as onshore wind or solar), its consequent higher unit cost and technological risk, and the lack of coordinated policies that allow both its deployment on a commercial scale and the associated cost reduction,” explains Raventos. “All these factors mean that the deployment of floating wind power is slower than expected.”

However, he adds, there is market interest, so it is important that pre-commercial projects are allowed to move forward to encourage technology development, better understand the impacts and ensure that the technology is ready for deployment by the end of this decade.

"In this sense, it is expected that testing platforms such as PLEMCAT in Catalonia, in which X1 Wind has been pre-selected to test its technology, play a decisive role, allowing not only to test and certify the technology, but also to better understand its potential impacts and introduce improvements that allow a sustainable and integrated operation with the environment and other uses of the sea,” adds Raventos.

The role of ports

Ports play a fundamental role in the development of offshore wind technology, as they are essential infrastructures for the construction and assembly of the large structures involved in the platforms. In addition, they can function as logistics centers for the transport of components and maintenance of the farms, as well as innovation centers in which to test new designs and technologies under controlled conditions.

"A large part of the components and prototypes installed in Europe have been manufactured or assembled in domestic ports. Our first partial-scale prototype (PivotBuoy project), for example, was manufactured near the port of Santander, north of Spain, and assembled in the port of La Luz in Las Palmas, Canary Islands. (see video above). “On the other hand,” explains Raventos, “our first commercial-scale prototype (NextFloat project) will be manufactured and assembled in the port of Tarragona (Catalonia). In the near future, we are confident that we will also be able to collaborate with the port of Barcelona, where X1 Wind's headquarters are located,” he says.

The report ‘A 2030 Vision for European Offshore Wind Ports: Trends and Opportunities’ also adds another important role that ports can play in the supply chain: that of converting energy generated at sea into renewable hydrogen.

Thus, offshore wind energy is presented as a fundamental solution to diversify the role of ports and attract investment, on the one hand, and to accelerate decarbonization and achieve a cleaner and more sustainable system, on the other.