Circular economy applied to industrial cooling: the pioneering case of Barcelona

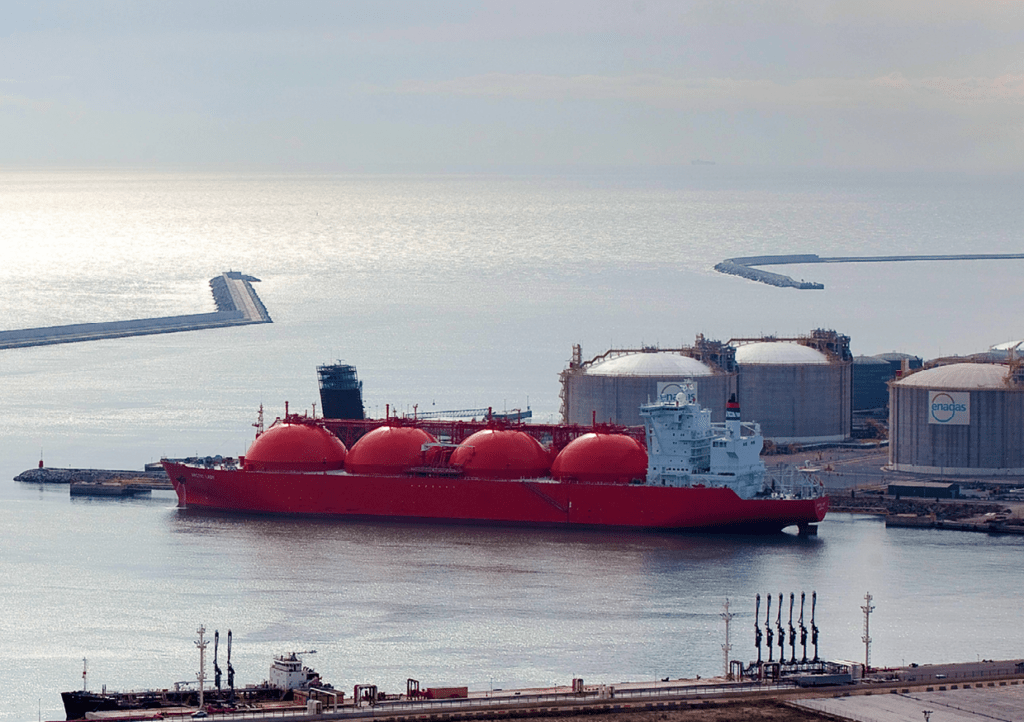

Barcelona is the first port to use the residual cold from the liquefied natural gas (LNG) regasification process as a sustainable energy source for industrial, tertiary, and residential uses, thanks to a unique and innovative system.

Barcelona, a pioneer in residual cold recovery

In 2009, the Barcelona City Council launched a public tender for the concession of a centralized system for the production and distribution of heating and cooling in the areas of the Zona Franca, the Port of Barcelona, the Marina del Prat Vermell neighborhood, part of L’Hospitalet de Llobregat, and ZAL-2 in El Prat de Llobregat, covering a total area of 17,900,000 m². Initially, cooling was generated conventionally using electricity.

- The tender included the recovery of residual cold from the liquefied natural gas (LNG) regasification plant operated by Enagás, located in the Port of Barcelona, with the aim of supplying a sustainable energy source for industrial, tertiary, and residential uses.

“This is the first urban cooling network developed in multiple phases,” recalls Francesc Estrada Berlanga, Director of Development at Ecoenergies Barcelona—a public-private company created as a result of the tender, 75.50% owned by Veolia, 17.50% by the Barcelona City Council, and 7.00% by the Copisa Group.

Before the connection with the Enagás Cold Generation Plant, cooling was produced at the Ecoenergies Central Plant using conventional systems for both positive and negative refrigeration, with both systems relying on electricity. “It was in December 2024 when we launched the connection with Enagás’ regasification plant and shut down the conventional cooling system,” explains Estrada Berlanga.

- Since going live, the system will have the capacity to distribute 131 GWh per year of thermal energy (at -20 ºC), locally generated, sustainable, low in carbon emissions, and cost-effective—equivalent to the energy needs of a city of 80,000 inhabitants.

The project included a first phase for the construction of the plants (Zona Franca and Marina) and the distribution network, which began in 2009, and a second phase involving the design and construction of the ecological cold recovery plant at the Port and the connecting network—the “cold pipeline”—to the Ecoenergies Barcelona plant in Zona Franca, with an investment of €120 million.

How does the innovative cold recovery system work?

Liquefied Natural Gas (LNG) arrives at the port in methane carriers, transported at a temperature of -160 °C. To be used, the gas must transition from a liquid to a gaseous state, which is achieved by raising its temperature to 5 °C using seawater.

“At -160 °C, any fluid that comes into contact with LNG would freeze, so we had to create an intermediate stage using a substance—ethanol—that requires no pumping, since it functions as a thermosiphon. This allows us to transfer the excess cold to a fluid at -20 °C without it freezing,” explains the Director of Development at Ecoenergies Barcelona.

This -20 °C fluid is what is distributed to end users through an underground network that delivers energy at different temperatures: 5 °C for air conditioning, and -10 °C or -20 °C for industrial uses.

The equipment inside this “cold box” consists of:

- 5 LNG–ethanol heat exchangers (5 x 3.6 MWth)

- 5 ethanol–thermal fluid -20 °C heat exchangers

- 7 thermal fluid pumps (160 kWe, 200 m³/h, 16 bar)

- Thermal fluid expansion tank

- LNG mixers

Previously, the cooling process used approximately 15 million m³/year of seawater to enable gasification. Once cooled, this seawater was discharged back into the sea, and the residual energy was lost.

“This new system allows us to recover that residual cold, which is now delivered to all end users. It’s a true innovation—not just in recovery, but also in its distribution and transport,” adds Estrada Berlanga.

The fact that the temperature of the carrier fluid circuit (glycolated water) is set at -20 °C is no coincidence. This specific temperature and fluid were chosen based on the complexity of the installation, transport requirements, a detailed analysis of Ecoenergies’ projected temperature demands, and a cost-benefit study at different temperature levels—which concluded that -20 °C was optimal.

“In any case,” notes the Director of Development at Ecoenergies Barcelona, “from that base temperature of -20 °C, we can supply other levels—such as -5 °C, -10 °C or -20 °C—depending on the use, thanks to exchange units that allow us to adjust the service temperature.”

Why is this solution so relevant?

Estrada Berlanga emphasizes that this is the first facility in the world to recover cold through this system, the result of a joint research and development effort between Enagás and Veolia. In fact, the project has been submitted for an award by the International Association of Ports and Harbors (IAPH).

One of its key advantages lies in the intermediate ethane cycle, which transfers cold from the LNG gasification process (upper side) to the thermal fluid (lower side). It functions as a thermosiphon, with a continuous liquid–gas cycle of ethane that requires no energy consumption. Moreover, since the cold is recovered rather than generated using electricity, the system avoids the emission of 42,000 tons of CO₂ annually, equivalent to the electricity that would have been used for conventional cold generation.

In addition, a cold energy storage system is planned at the Zona Franca plant, enabling the absorption of all the cold generated during the regasification process at ENAGAS. This increases flexibility to better match the demand curve of Ecoenergies' customers, which does not necessarily align with the arrival of LNG transport ships at the Port of Barcelona. It also strengthens the circular economy model by maximizing the use of recovered residual energy.

Before the system was launched, two pilot projects were conducted in 2019 and 2021, mainly to prepare for the next phase of the cold distribution network, which is expected to serve Mercabarna, Barcelona’s central wholesale market, by 2027.

“Different types of products and technologies were analyzed to determine which fluid to use for transferring cold from the Enagás plant to the Ecoenergies Barcelona facility. In the end, it was a cost–benefit exercise that considered the required infrastructure, since the civil works were particularly complex,” he explains.

Replicability of the Project

Given the increasing number of geopolitical and climate-related disruptions that have become the new normal, it is essential for ports and cities to be energy-independent in the face of such scenarios.

“This is a geostrategic, political, and technical issue,” explains Estrada Berlanga. “Events like the gas supply cuts to Germany by Russia in 2022 or the droughts in Colombia caused by the El Niño phenomenon—in a country that relies entirely on hydroelectric power—have triggered major energy crises. Diversifying sources, since they are all compatible, is the way forward.”

According to Estrada Berlanga, demand for this type of energy will grow in the coming years due to the increasing activity in cold logistics, making it “absolutely essential” to have an alternative source. As for gas, he adds, its supply is guaranteed for the next 50 years.

Innovative initiatives like this one enable ports, port areas, and nearby cities to face the challenges of climate change. In addition to transforming Barcelona’s energy model, it also opens the door for this technology to be replicated worldwide.

According to an analysis by Veolia and Enagás, there are currently more than 174 LNG terminals worldwide: 152 for import and 22 for export.

- Thirty percent of the import terminals have the potential to replicate Barcelona’s cold recovery project.