Personalised service 24 hours a day

The robotised dry dock also provides better service for users than a traditional dry dock, as it can be personalised. "When a client decides to leave their vessel here, the first thing they have to do is an adjustment manoeuvre with the system. This calibrates the machine to adapt it to the characteristics of each boat, including the length, height and width." This information is used to create a unique ID tag for each vessel. "When a vessel arrives at the marina, the system identifies it and adapts the transport elements to its characteristics. It also takes it to a personalised berth, minimising the impact on the hull while it is at Marina Vela," explains the technician.

Before entering the storage area, "the hull is cleaned with pressurised water to eliminate any salt, which could damage it. Then it is dried with fans to prevent the dampness from getting into the facility," explains Pascual. All of these options (cleaning the hull, lifting the boat with robotic arms, transport inside the dry dock to its personalised berth) are done in record time: just five or six minutes. Moreover, only one person is involved in the whole process (who, in fact, simply supervises the operation and makes sure that there isn't anyone still in the vessel when it enters the facility). This means the dry dock can run continuously. To make sure the service can be provided with very little human intervention and as quickly as possible, "a smartphone app has been created for boat owners to book their timeslot to drop off or pick up their vessel from the marina."

All of these "technological advances," Pascual believes, "will allow us to provide better service for recreational sailors," but also comprise a more sustainable solution environmentally, as the system offers more berths in less space, as well as minimising the impact on the marine environment. In short, after in-depth study, "it is the most sustainable solution, both economically and environmentally, that we could find."

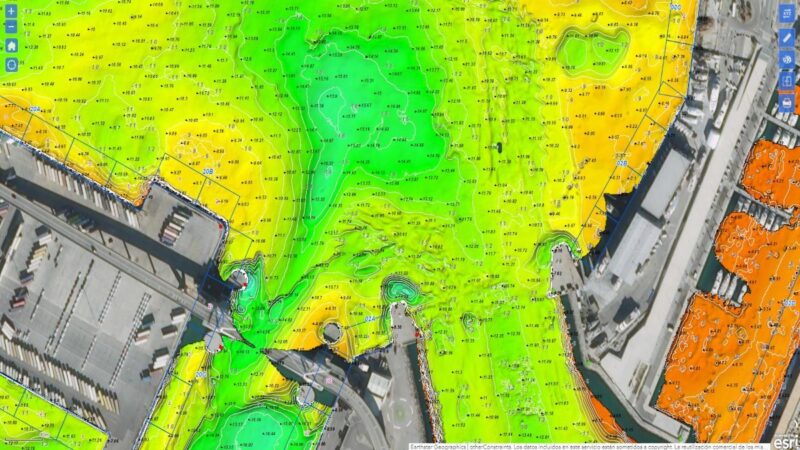

Marina Vela during its construction process [Image by Port de Barcelona]

Marina Vela during its construction process [Image by Port de Barcelona]

Marina Vela during its construction process [Image by Port de Barcelona]

Marina Vela during its construction process [Image by Port de Barcelona]