Digital twins systems allow ports to achieve operational efficiency, managing data and avoiding dangerous situations. (Photo: Port of Barcelona).

Digital twins systems allow ports to achieve operational efficiency, managing data and avoiding dangerous situations. (Photo: Port of Barcelona).

Digital twins for safer and more efficient port decisions

Digital twins, a virtual representation of a physical system across its entire life-cycle, help ports turn extensive indexes of data into digestible models of port life, in which information is easily shared and understood. With the use of new technology, digital twins are revolutionizing the way ports make decisions, offer value in operational efficiency, manage data, and prevent dangerous situations from arising. In fact, Gartner predicts that by 2021, half of large industrial companies will use digital twins, resulting in those organizations gaining a 10% improvement in effectiveness.

Digital twins systems allow ports to achieve operational efficiency, managing data and avoiding dangerous situations. (Photo: Port of Barcelona).

Digital twins systems allow ports to achieve operational efficiency, managing data and avoiding dangerous situations. (Photo: Port of Barcelona).

As a new hire at the Port of Montreal, the first day on the job would include the expected introduction to port safety - but in an unconventional manner. Rather than training on the ground, port personnel would first be handed a video game controller.

This isn’t just any video game, of course. It’s a virtual simulation -or digital twin- of the Port of Montreal that enables staff to come into contact with typical accidents and disturbances before ever facing them in real life.

These preventative simulations are designed to give users the opportunity to combat potential high-risk circumstances without any of the danger. From cargo fires to toxic spills, this digital twin enables port personnel to experience possible occurrences without ever stepping foot in the port.

With a virtual toolbox, users go through their checklists as if the disaster was occurring in real-time, giving them a safer way to practice port security. And, just like in a video game, the difficulty of the simulation can be increased as trainees gain more skills and experiences.

But this technology means more than just an interactive way to be introduced to the day-to-day of port procedure. It’s also changing the way in which ports operate their business, helping them to make smarter, faster, and safer decisions.

This is just one example of how digital twins can help ports improve their service. However, the effects of this innovative technology are much farther reaching than just this one definition.

What is a digital twin? The technology that’s defined by the vision behind it

A digital twin is a virtual representation of a physical system across its entire lifecycle. While the popularity of creating digital twin technology through IoT networks is growing in the ports sector, it’s still a new idea with a malleable definition depending on the vision of the port designing it. And this vision is greatly impacted by the motivating factors that lead to its development.

From the Port of Montreal’s video game-style simulation to a 5G network at the Port of Hamburg, ports around the world are demonstrating that different needs and challenges are inspiring very different digital twin models.

Here, we look at a few cases in which ports globally have been inspired to develop new technology that helps share their wealth of information in comprehensive ways to ultimately create smarter and safer port experiences.

Situational awareness with the Port of Antwerp

The Port of Antwerp, with its troves of data from multiple port systems, was interested in learning how augmented reality could impact their port operations. That’s why they set out to design APICA, a digital twin in the form of an augmented layer on top of a picture that gives users complete situational awareness of port movements.

“Everyone has their own definition of what a digital twin is.”

Piet Opstaele, Innovation Lead, Port of Antwerp

As one of the largest ports of the world in terms of area, a digital twin of this nature gives the user a perspective on the port that would otherwise be impossible. With an 8-D outlook that brings 12 different databases of information together, users can instantly note the number of ships in port or even wind turbine profits in real-time.

According to Piet Opstaele, Innovation Lead at the Port of Antwerp, digital twins are not about simulations - but simulation models. And their simulation model provides them with an unprecedented situational awareness of:

- Cargo movements

- Geographic information systems

- 7 digital connected locks

- Drone flight trajectories

- Waterways (over 500 cameras for supervising)

- And can detect illegal barges, sending automatic alerts when necessary

Digital replication with the Port of Rotterdam (with IBM IoT)

In partnership with the IBM IoT network, the Port of Rotterdam has created their own digital clone that tracks ship movements, infrastructure, weather, geographical information, and water depth data - all with complete accuracy and precision.

They have two pieces of technology in place that are helping them accomplish this new level of innovation:

The first is their Portbase Port System Community System, which is equal parts application layer, platform, and information database. This groundbreaking system shares information across the port through bilateral connections.

The second piece of technology is a fully automated deep-sea terminal with automated guided vehicles, which has upgraded the ports ability to monitor and improve deep sea movement.

All of this helps lower fuel consumption rates, facilitate cost-effective per-ship payloads and ensure the safe arrival of cargo. All of which support their mission to maintain a strict standard of safety, while better understanding the areas of the port that need improvement.

Smarter control with the Port of Hamburg

With 95% of its logistics processes digitized, the Port of Hamburg is already covering rail, water, and road traffic with their automated data collection and analysis system that is used by 2,000 companies. Thanks to this effort, the integration of augmented reality digital twin technology helps them to visualize all of this digital information in one place.

Another side of the digital twin project that is helping the port increase their ability to streamline processes is their Project 5G MoNarch.

This means upgrading their services in a number of ways including improving traffic light control for better traffic flow, integrating mobile sensors on barges that are connected through 5G, and, with the bigger bandwidth, implementing AR and VR 360 pictures of the port – which all can be monitored through their digital twin.

With this 5G technology integrated into their digital twin model, the Port of Hamburg is maintaining smarter control over each moving part at port.

Operational efficiency with the Port of Singapore

With their Centre for Excellence in Modelling and Simulation of Next Generation Ports (C4NGP) already established, the Port of Singapore has tall orders to fill in terms of maintaining high standards for digital practices.

The centre is currently moving forward with plans to help researchers evaluate the impact layout design and have on the efficiency of their Tuas Terminal with their own version of a digital twin simulation that is still in development. This technology is expected to improve operational efficiency with handling natural disasters and extreme weather conditions when it releases in 2021.

All of these innovative advancements are pushing the boundaries of what’s possible in terms of efficiency, service, and global cargo movement.

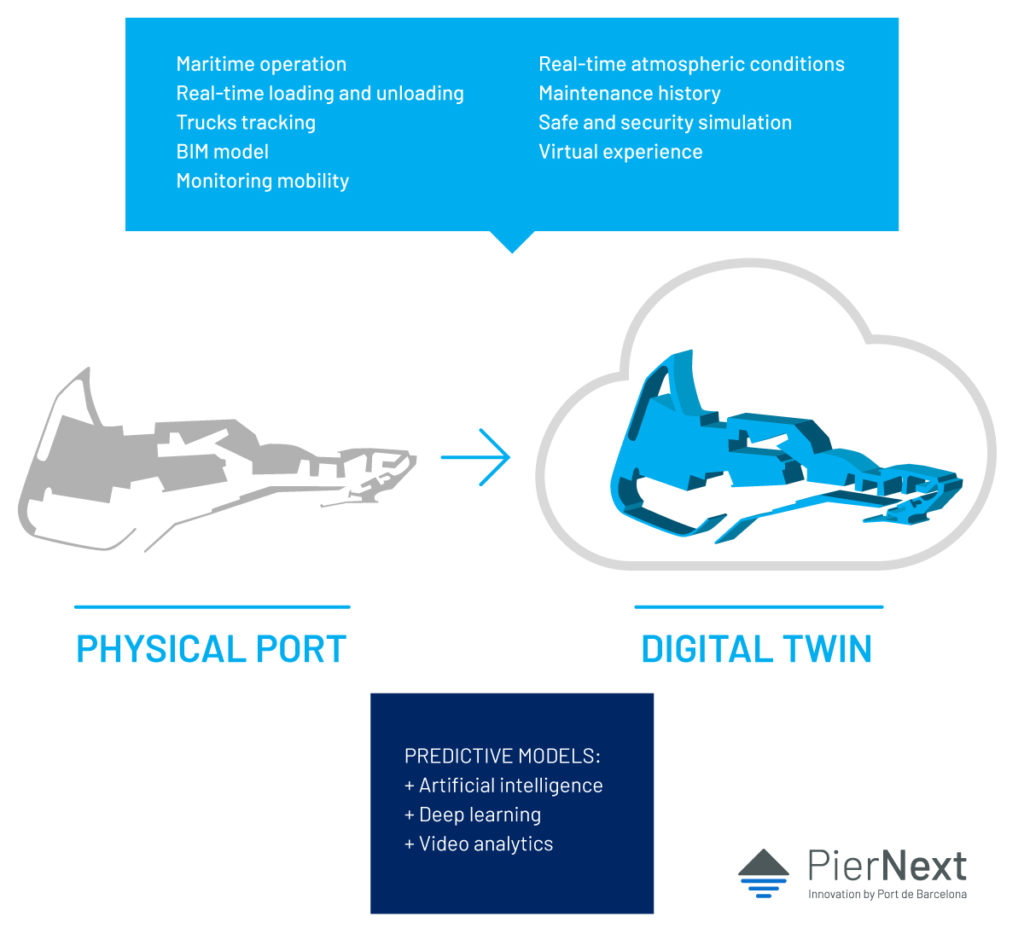

The port of Barcelona: from monitoring to predicting

For years, the port of Barcelona has registered and monitored the port operations of all relevant agents and operators. These operations include the approaching of ships, pilot assistance, tugboat operations, berthing and mooring operations, cargo loading and unloading, crane operations, container racking within the terminals, trucks or trains receiving cargo, vehicle entries and exits, etc.

Thanks to all this gathered information and its digital replica, port managers can reproduce the status of all these operations at any given moment on a 2D map. These registered data are already used for analysis and decision-making purposes, but not in real time. The challenge of incorporating a twin port serves three purposes:

- To improve the “operational” representation of the port.

- To obtain a real-time representation of said operations.

- To manage the port more smartly.

To implement the twin port, the port of Barcelona is developing the following technologies:

- 3D representation of the port area to digitally represent port operations using graphs and video images.

- 5G communications and Wi-Fi to connect more sensors and improve communications in real time.

- Artificial intelligence to interpret the sensor and business data and make some decisions “automatically”.

- Video image analysis, like a very powerful sensor able to count, detect changes, send notices, measure available space, etc.

- API programme open to the operators to improve dataflow in real time.

This technological deployment has the following goals:

- To represent data in real time on a digital twin model. This will help managers make decisions in real time.

- To improve the productivity of port operations.

- To guarantee the safety of businesses and port workers.

- To improve the transparency of operations for end clients by providing information relevant to their business in real time.

- To incorporate predictive abilities in ship loading/unloading and container pick-up/delivery operations.

The future of digital twins and ports

While no digital twin is the same, each port has crossover in the goals they have in mind for this technology.

Safety is at the forefront of the digital twin revolution, giving ports the opportunity to increase awareness over the entirety of their surface area including waterways. This new level of safety will not only prevent dangerous disturbances, it will help establish control over inefficiencies and improve the speed of deliveries.

Digital twins also enable ports to look forward to a more streamlined communication and data management between IoT networks and ports, providing anyone who steps foot into a port with a better experience.

As this digital twin technology enhances, the future of ports can only expect to see further optimization and more efficient processes. And, perhaps in the near future, everyone can expect to be introduced to port life through their own virtual experience.