The first ship’s propoller made with additive manufacturing at Rotterdam’s RAMLAB. Image by RAMLAB.

The first ship’s propoller made with additive manufacturing at Rotterdam’s RAMLAB. Image by RAMLAB.

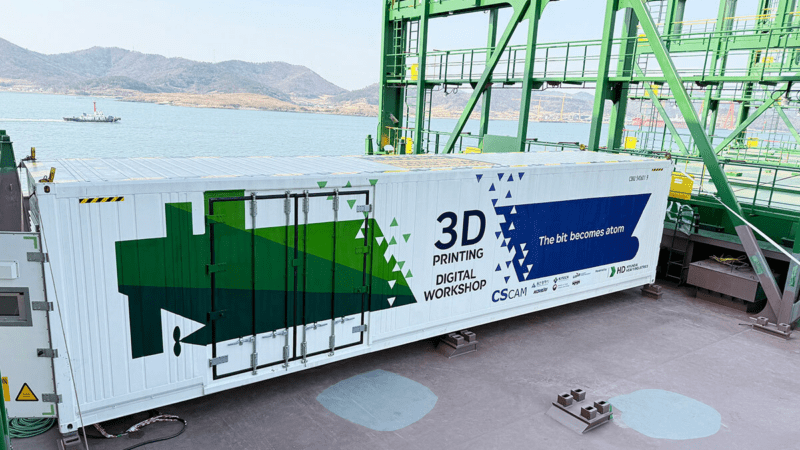

37% Of Container Traffic, At Risk Of Disappearing By 3D Printing

3D printing technology will be one of the next technological revolutions with the greatest effect on production and sales flows. Clearly, any innovation in the manufacturing industry has the potential to transform the whole supply chain.

The first ship’s propoller made with additive manufacturing at Rotterdam’s RAMLAB. Image by RAMLAB.

The first ship’s propoller made with additive manufacturing at Rotterdam’s RAMLAB. Image by RAMLAB.

3D printing is considered a type of additive manufacturing that "prints" (creates) a three-dimensional object by adding layers of a specific material (normally plastic, metal alloys or ceramic, but even salt and sugar) and therefore differs from traditional "subtractive" manufacturing methods.

Logistical changes

This type of manufacturing will have an impact on current procedures and lead to de-globalisation. It will also lead to a drop in container transport. According to a study by PricewaterhouseCoopers (PwC), 41% of air cargo business and 37% of ocean cargo business is at risk due to 3D printing. Likewise, distribution flows will also change. For example, experts expect an increase in sea transport of raw materials to the detriment of finished products. To mitigate the effects of this, ports will have to develop new operating strategies, such as becoming 3D printing hubs.

3D printing technology will transform distribution, risking 37% of ocean cargo business and 41% of the air cargo business.

3D printing will be used to finish the process of producing spare parts and reduce the need for stocks with on-demand production. Likewise, a new set of quality standards will be developed for objects made with additive manufacturing (AM).

The ship's propeller is built with 298 layers of metal. Image by RAMLAB.

The case of the Port of Rotterdam

Some ports have already begun planning their strategy to make the most of this technology and limit its impact on logistics and sales flows. One of these is the Port of Rotterdam.

This Dutch port's strategy is to become a centre of 3D printing for sea transport and offshore industry. The first big step towards this goal was opening RAMLAB (Rotterdam Additive Manufacturing LAB) in November 2016. RAMLAB is the first 3D metal printing laboratory in the world for the maritime sector. It is located on the RDM Rotterdam Innovation Dock and equipped with two 3D metal printing systems. The founding partners are the Port of Rotterdam, InnovationQuarter and RDM Makerspace. Furthermore, they have also created a powerful network of associates that provide the hardware, software and guidance on certification of additive manufacturing processes.

The Port of Rotterdam opened RAMLAB, is the first 3D metal printing laboratory in the world for the maritime sector.

First steps

In the beginning, RAMLAB focused on manufacturing metal spare parts for maritime use. In addition to the companies with ties to the port, some from other sectors also participated, including Fokker (aerospace industry) and Siemens (software development). So far, in association with the Damen Shipyards Group, RAMLAB has manufactured the first 3D-printed ship propeller in the world, successfully passing all the required quality tests. This propeller, which weighs 400 kg and has a diameter of 1.3 metres, is a milestone in the efforts to perfect this relatively young technology. "A metal printer adds material layer by layer, which means the end product differs from a ship propeller that has been cast in the traditional manner," says Kees Custers, Project Engineer in Damen’s R&D department. In this case, "the propeller was printed with a nickel, aluminium bronze alloy." The results are promising: additive manufacturing speeds up production, takes fewer tools and less investment, optimises design and considerably shortens delivery time and stock costs.RAMLAB's mission statement is that industrial spare parts should always be available wherever they’re needed, whenever they’re needed. Furthermore, they should also meet or exceed the end user’s quality requirements at a competitive price. The end goal is to accelerate the adoption of additive manufacturing technology by providing partners with easy access to the entire value chain.

RAMLAB focuses on manufacturing industrial spare metal parts on demand and at a competitive price.