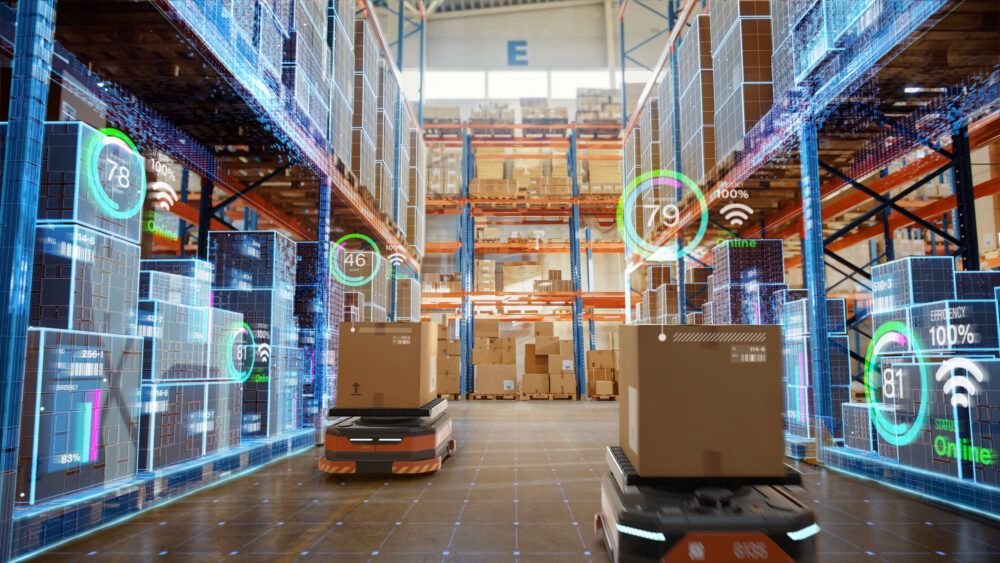

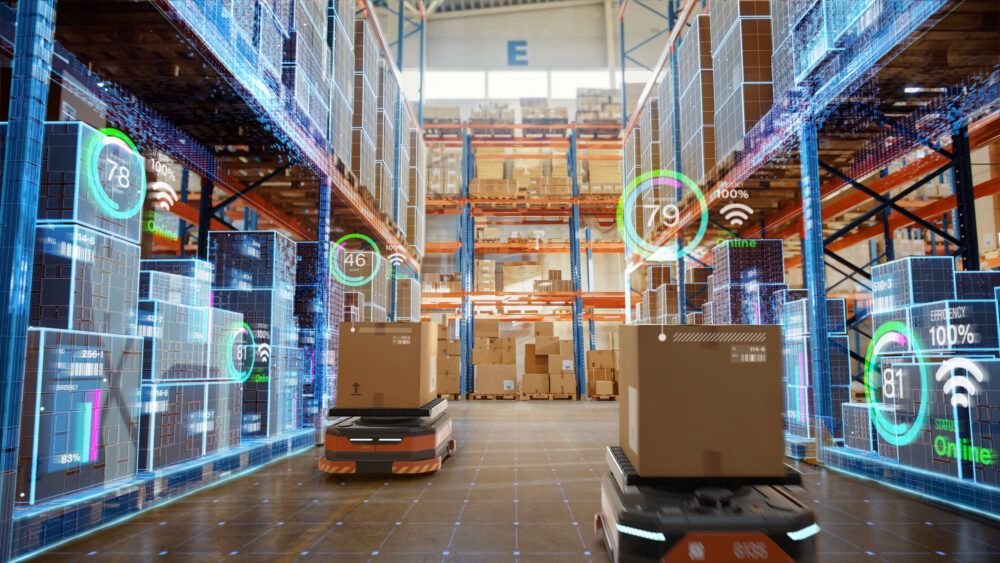

Since the 1950s or 1960s, robots have been working in factories, capable of knowing what is happening in their production line. (GettyImages)

Since the 1950s or 1960s, robots have been working in factories, capable of knowing what is happening in their production line. (GettyImages)

The new laws of robotics set foot on port logistics

Drones and mobile robots are already a reality in port logistics. They have the ability to understand their environment and make their own decisions. They are the protagonists of the 'robota' revolution in smartports. 'Robota' in Czech means "hard work" and is the word chosen by playwright Karel Čapek in 1920 for a science fiction play. three decades later, Isaac Asimov coined robotic laws in I, Robot. Since then we knew that sooner or later robots, at different levels of sophistication, would become widespread in industrial economic life. This day has finally arrived.

Posted on

01.21.2022

Since the 1950s or 1960s, robots have been working in factories, capable of knowing what is happening in their production line. (GettyImages)

Since the 1950s or 1960s, robots have been working in factories, capable of knowing what is happening in their production line. (GettyImages)