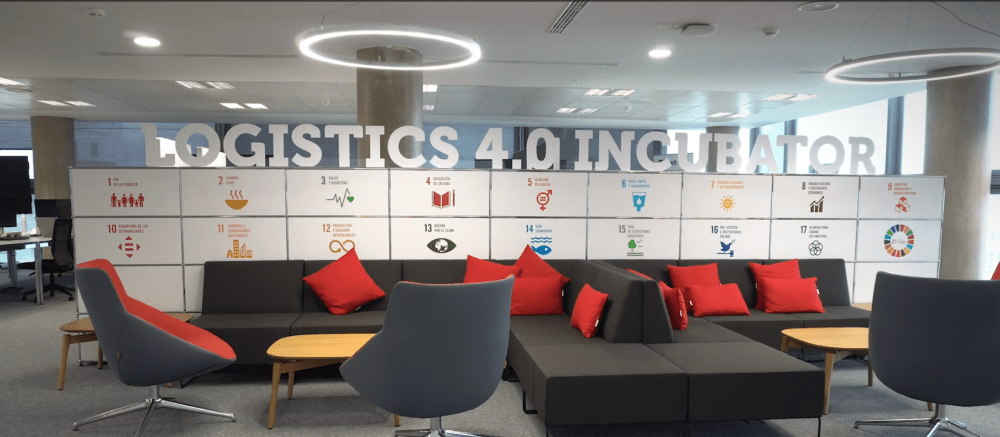

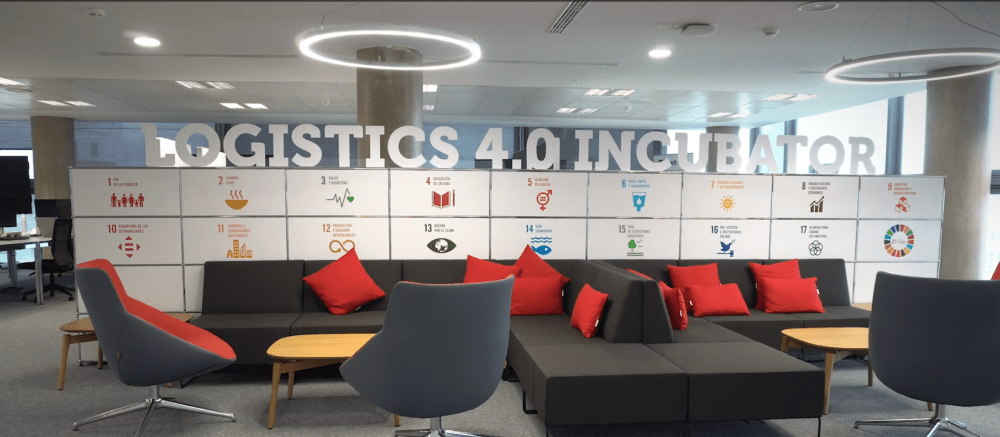

In July 2023, the high-tech incubator for logistics 4.0 was launched. (PierNext)

In July 2023, the high-tech incubator for logistics 4.0 was launched. (PierNext)

Logistics 4.0 has a dedicated incubator at the Consorci de la Zona Franca de Barcelona

Robotics, automated warehouses, the Internet of Things (IoT), Big Data and green logistics are technologies with great potential to impact the supply chain. However, their implementation is still at an incipient stage, a scenario that the Consorci de la Zona Franca’s Logistics 4.0 incubatorhopes to change by placing innovation at the heart of this leading industrial estate.

In July 2023, the high-tech incubator for logistics 4.0 was launched. (PierNext)

In July 2023, the high-tech incubator for logistics 4.0 was launched. (PierNext)

Spain's first incubator dedicated to Industry 4.0

Located in the Consorcio de la Zona Franca de Barcelona (CZFB), the High Technology Logistics 4.0 incubator was created with the aim of adding technological value to products and processes of companies in the sector through a selection of start-ups with solutions applicable to logistics.

The selected start-ups receive various support from CZFB, the Incyde Foundation and Feder Funds. Helena Gutiérrez, from CZFB's incubation department, highlights, in addition to an allocated budget of between €10,000 and €30,000 to carry out their technological innovation, the mentoring and networking opportunities offered.

"At the BNEW, which takes place in October, they will have the opportunity to present their proposals to investors and in November they will participate in the Smart City Expo World Congress. We want them to make the most of their time with us," he explains.

CZFB communications director Lluís López points out that the 4.0 Incubator is part of the strategic plan launched in 2019 which, among its objectives, seeks to generate jobs and promote the economy of the business fabric.

"The plan includes innovation and sustainability projects that began more than four years ago, with the launch of the 3D Printing Incubator," he recalls.

On the pioneering nature of the incubator, López points out that the strategic location of the CZFB "is practically unique in the whole of Europe." "We are next to the port and airport, Mercabarna, the Logistics Activities Zone... on a logistical level it is unbeatable," he stresses.

And the start-ups are already beginning to see the results. “We recently surveyed them and 79% of them said that they plan to hire someone for next year, which is a great sign for the future," he says.

Logistics and technology, closer

The location and management of the more than 280 companies located in this industrial estate, ranging from SMEs to multinationals, allows the CZFB to bring disruptive solutions to a sector with a reputation for being traditional.

"The fact that this incubator is here is a way for start-ups to quickly reach a first agreement with a potential client, collaborator or investor. It is important to generate this feedback between start-ups and corporations," says Joaquim Poley, product manager for innovation at CZFB.

He explains that most of the selected start-ups are in the first phase of activity. "There are start-ups that are developing technology, pivoting and are not clearly finding their differential business model. This is the cycle of a start-up, to develop innovation until they really find the product associated with a specific and differential model that makes them stand out from their competition and is market-orientated.”

Regarding the relationship that the logistics sector traditionally has with start-ups, Poley explains that many of them see technology as something inaccessible or that they have typically contracted through consultancies.

"That's why we are going to develop networking sessions between the start-ups themselves and these companies, to break down the idea that developing technological improvements or innovations is complicated or that it has a high cost. The fact that they can reach a collaboration agreement with a start-up that has already developed a viable product for a specific solution is one of the values that we also believe the Incubator 4.0 will bring, not only to the start-ups, but also to the more mature business fabric that we have located in the Zona Franca," he explains.

The transversality of the start-ups

One of the start-ups selected is Columat, which has developed intelligent lockers that support a wide range of temperatures, from frozen to hot, so that its customers can deposit their orders and the end customer can pick them up when it is most convenient for them. The software they use allows for the adaptation and traceability of all the processes and complexities of last mile delivery.

"We work for the retail sector, specifically food, pharmaceuticals and other companies with a high volume of orders. We also work for the real estate sector, i.e. offices, buildings, coworkings and those spaces with a large volume of people who need to receive and send packages and that thanks to our solution can do so autonomously and 24/7," says Albert Bladas, its CEO.

The temperature system is modular and each column is adapted to the temperature required by the product placed inside, which is generated and controlled by an engine.

Bladas explains that he expects the incubator to help propel Columat to the next level by facilitating "strategic collaborations" in the logistics, retail or ICT sectors to continue adding value.

Another radically different example is Hardman, a platform that helps large shippers and distributors digitise and optimise processes related to the entry and exit of trucks in and out their plants.

In the words of its CEO, Óscar Calaf, Hardman innovates in setting up a process that works like a pit stop. "The door opens, the truck arrives, we hand over the digital documentation to the driver, the loading is done and it leaves for its destination in the shortest possible time."

"The average waiting time our customers were experiencing at a logistics platform was one and a half hours. After a year with us it is approximately three minutes and 59 seconds," he explains.

This means savings on several fronts. Calaf gives the example of a company that moves 100 trucks a day, for which these savings amount to 7 million kilos of CO2 not emitted into the atmosphere or 1.4 million in immobilised material.

"There is a lot of innovation in the last mile, in intelligent vehicles, drones that take packages home... but the digitalisation and automation of processes is what generates the most savings for a company," he says.

Calaf shares that, after a pivoting phase, Hardman is at a turning point. After demonstrating that his product has a place in the market, he hopes that Incubator 4.0. will help him to scale "in a remarkable way."

Augmented and virtual reality are the two technologies Jotavirtual works with, a start-up that virtualises built space so that it can be navigated in an interactive and immersive way.

"Within the virtual space, we can add information points that allow us to identify parcels in a warehouse or explain to the operator how to handle packaging," explains Emma Urbina, co-founder of Jotavirtual.

The start-up began its activity during the pandemic, setting up virtual educational spaces so that students could continue with their classes.

Later, they did the same in the real estate sector, but not only inside the houses but also in the immediate vicinity, in order to provide the maximum information to interested buyers.

Regarding the logistics sector, Urbina values the work they are developing with other start-ups they have met in the Incubator 4.0, such as Estoko Logistics, with whom they are testing the digitisation of warehouses and routes.

"These tests will allow us to have a model ready when our product goes to market. Our colleagues act as customers, giving us feedback on what works and what doesn't and, based on their opinion, we are fine-tuning our idea," she describes.

The CZFB Incubator 4.0 hopes to be this bridge that connects logistics companies with the disruption that start-ups represent. Innovation in the sector has never been closer.