Despite the strength of European rail, the industry relies in part on outdated systems that are becoming increasingly difficult to maintain. (Getty Images)

Despite the strength of European rail, the industry relies in part on outdated systems that are becoming increasingly difficult to maintain. (Getty Images)

Rail: the digitalisation of a strategic transport system

Rail is the most efficient land transport. This is why the EU is devoting a lot of resources to increasing the modal share of rail freight transport. But it urgently needs to be digitalised and automated to increase its safety and reliability.

Albert González is Head of IT Management Services at the Port of Barcelona.

Despite the strength of European rail, the industry relies in part on outdated systems that are becoming increasingly difficult to maintain. (Getty Images)

Despite the strength of European rail, the industry relies in part on outdated systems that are becoming increasingly difficult to maintain. (Getty Images)

Rail, the transport of a decarbonised Europe

Why is rail transport more efficient? Because of a combination of technical factors.

- Firstly, because of the minimal rolling resistance, the elastic deformation of the wheel-rail contact is comparatively low, as both elements are made of steel.

- Secondly, due to optimum aerodynamic drag on long trains, the friction depends mainly on the vehicle cross-section, not on the length. This results in minimal energy consumption.

- If we add to this the high transport capacity of a train, especially when we achieve the European standards of 740 m in length, and boost the electrification of railway lines, we obtain a much more sustainable and competitive mode of transport than road for medium and long distances.

Thus, according to CER data, transport generates 31% of transport energy consumption in the European Union. Rail, for its part, is seven times more efficient than road transport. In terms of emissions, rail accounts for 0.4% of all transport.

Target 2030. In its 2011 White Paper, the European Commission set a target of shifting 30% of road freight transport over 300 km to rail by that year. Or to inland waterway transport.

By 2050, the percentage should increase to 50%. In addition to supporting these decarbonisation targets, the shift will ease road congestion, reduce pressure on road infrastructure from heavier loads and reduce the risks associated with transporting dangerous goods.

But the train is not making enough progress. Despite the political push, the share of rail freight transport remains at around 20%. It has even fallen in some EU countries.

The urgent digitalisation of rail

Outdated systems and obsolete technology. The report 'Digitising Europe's railways: A call to action' (McKinsey in 2020) stated that, despite the strength of Europe's railways, the sector relies in part on outdated systems that are increasingly difficult to maintain. Some major European railways have several types of interlockings, in some cases more than a century old, and use very obsolete technology.

What is a railway interlocking? It is the system that is responsible for controlling the operation of all devices on the track to ensure safe compliance with dependency, operating orders and restrictions, so as to allow trains to run or park at stations or on routes under safe conditions.

Interoperability of networks between countries. Legislation on the European Rail Traffic Management System (ERTMS), passed in 2000, has led to some technological improvements, but progress to date has been slow. ERTMS is the result of a European project that emerged in 1990 with the aim of developing a common ATP (Automatic Train Protection) system that would facilitate interoperability between the different networks, overcoming the differences in the various national systems.

ERTMS architecture has four levels of development. Each level of ERTMS would improve the functionalities of the previous one, allowing shorter intervals between trains

ERTMS pillars and levels of development

The ERTMS system is based on three pillars: the on-board equipment, the beacons and the GSM-R radio transmission system. Its operation, in turn, is based on two components:

- The European Train Control System, ETCS. An on-board computer compares the transmitted train speed with the maximum permitted speed and, if this is exceeded, reduces the speed.

- The Global System for Mobile Communications for Railways, GSM-R. Via radio, it allows the exchange of information via radio between the train and the track and control centres.

The ERTMS architecture has four levels of development. Each level of ERTMS would improve the functionalities of the previous one, allowing shorter intervals between trains. In other words, increasing infrastructure capacity and reducing field equipment:

- Level 0 is equivalent to conventional systems (NOT ERTMS). They provide discontinuous information by means of maximum speed beacons supplemented by lateral signalling. The driver has to pay attention to the side signs and speed indications on his driver's desk display, if he fails, makes a mistake or does not respect the limitations or the signs, the equipment applies the automatic brake.

- ERTMS level 1 is a continuous target distance system in which the information received by the train from the beacons is supplemented by the information received via GSM-R. The location of the train on the track is determined by the train's location on the track. The location of the train on the track is still done by road circuits. Lateral signalling is dispensable and is only used in degraded situations. The driver receives the information on the cab panels and only acts accordingly. In case of deviation from the defined operating conditions for train running, the system adjusts the parameters and brakes the train if necessary.

ERTMS level 1 allows trains to reach a speed to around 300 km/h with one train every five and a half minutes.

- ERTMS level 2 is a continuous mobile blocking system in which the train communicates its position and receives movement authorisations depending on the track status via GSM-R. This level imposes a mobile canton in which the train is in the position and receives movement authorisations depending on the track status via the GSM-R system. This level imposes a mobile canton on the traffic, can operate without the need for track and lateral signalling circuits and theoretically with enhanced level 1 functionalities.

ERTMS level 2 allows up to 350 km/h with a train every 2.5 minutes.

- Level 3, under development. This level has neither track circuits nor lateral signalling. The situation of each train is generated by the train itself thanks to GNSS (Galileo, or GPS) or even GSM-R. Each train creates its own mobile canton (safe space up to the previous train) according to the speed of both trains.

ERTMS 3 theoretically allows up to 500 km/h with one train every minute.

The digitalisation train is slow moving. A PricewaterhouseCoopers report states that in 2020 only 14% of the EU rail network was equipped with ERTMS infrastructure (Level 1 or 2). At the current rate of growth, the proportion will be 25% in 2030 and 35% in 2040. This implies the need to finally take up the challenge of digitisation.

The recommendation is to implement digitalisation and automation to modernise the railway system and increase its safety, reliability and comfort.

The 5 axes to digitalise the railways

Innotrans, the railway fair held in Berlin was attended by important companies in the sector such as Zedas, Siemens, Hitachi Rail, Alstom, Thales, CAFF, Rail Cube, SISCOG, GMV, Cargo Rail, Indra, Hacon, Ericsson and Ardanuy.

As a result of a series of working meetings, five main axes were identified in which the most important advances in railway digitalisation are being made:

1. Digitalising and interconnecting infrastructures

- The non-interconnected transport infrastructure has reached its limits, digitalisation is a necessary change.

- Interlockings are the centrepiece of the railway infrastructure. The relay interlockings that were established many decades ago have evolved into a second generation of electronic interlockings....

- ...but today a newer and more modern technology has been developed, the digital interlocking, which features an IP architecture based on standardised interfaces, the switching commands are sent digitally to the signalling equipment on the track via an IP network.

This has the huge advantage of not needing kilometres of cable hose to connect each individual interlocking device, as an IP network can send and receive information from devices over longer distances (such as signals and axle counters), and can also move to a centralised interlocking architecture that can control a large number of track elements.

The new digital and centralised interlocking technology is the basis for higher capacities and improved punctuality in rail transport.

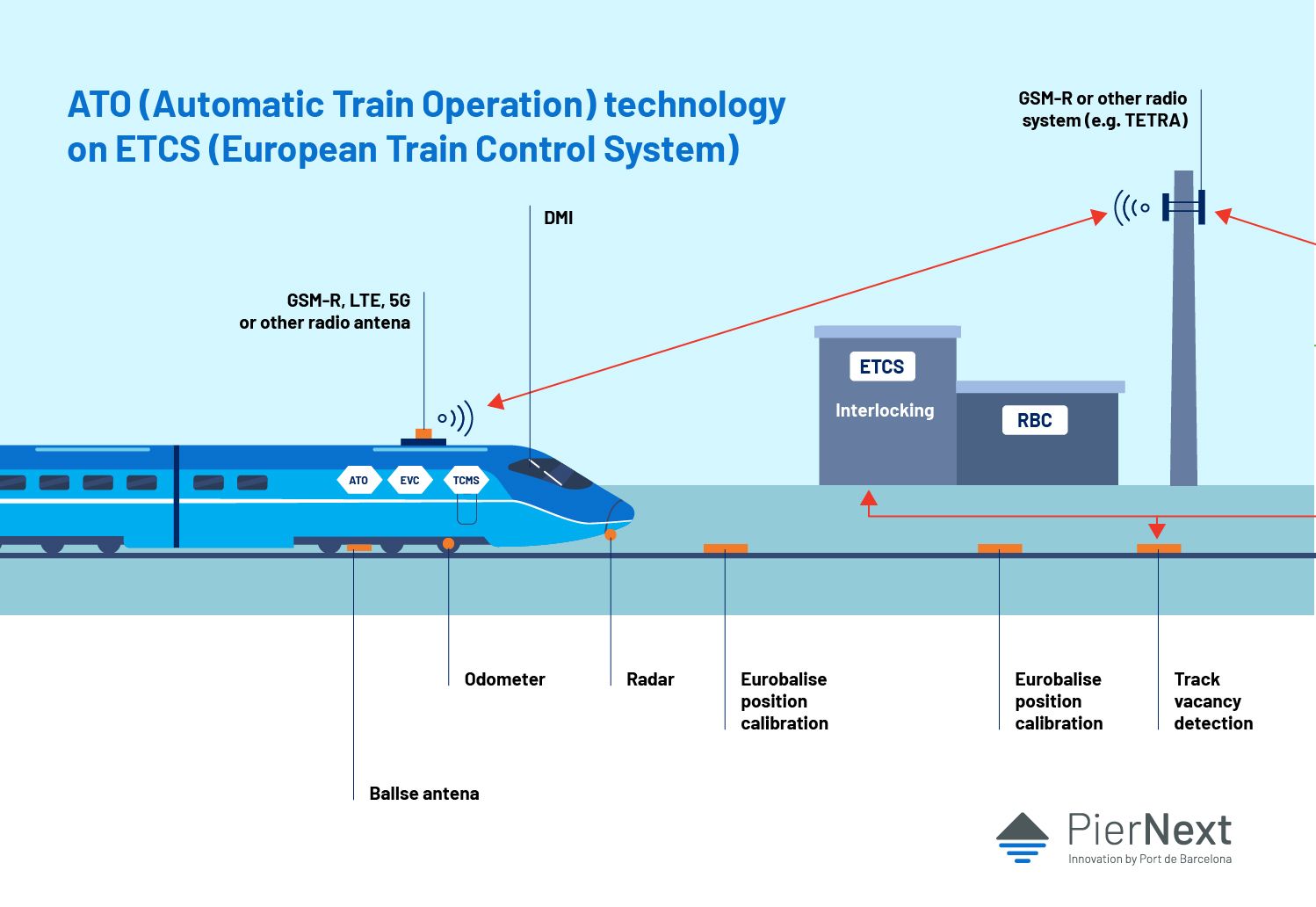

2. Automation as a foundation

The main manufacturers of railway infrastructure and signalling systems, such as Alstom, CAFF, Thales and Siemens, are strongly committed to further progress in the deployment of European standards such as ERTMS/ETCS and technologies such as ATO (Automatic Train Operation) over ETCS (European Train Control System), which can be considered as the basis for comprehensive data recording and automation.

How does ATO over ETCS technology work?

- The trackside ATO system collects static and dynamic line and timetable data provided by the traffic management systems and transfers it to the vehicle.

- Based on the available infrastructure, track and timetable data, the on-board system calculates the optimal travel profile in real time, and controls the traction and braking systems of the vehicle in automatic train paths.

- The driver is continuously informed of all procedures via a display. As a result, energy consumption is reduced and traffic flow and capacity are significantly improved, and the automatic braking of ATO over ETCS shortens braking distances.

4G/5G networks

- While the European ERTMS standard has so far been based on GSMR communications, a very robust technology but with low bandwidth and very limited in the exchange of train-ground information, the first wireless connections between interlockings are currently being made using 4G/5G technology.

- However, it remains to be seen to what extent these networks will have to be provided by private and/or public telephone operators, given that the coverage of the territory in which the trains run and the security standards applied to these communications must be taken into account.

Digital automatic coupling

- Another line of automation is digital automatic coupling (DAC) on freight wagons, an initiative to increase connectivity and efficiency in the composition of rail wagon convoys at intermodal terminals.

- This technology will automatically connect freight wagons as well as their power, data and compressed air lines. Since most goods trains are still coupled manually, DAC makes this process much more efficient and relieves the strain on rail workers.

- The DAC4EU consortium led by Deutsche Bahn has begun testing the use of digital automatic coupling (DAC) on freight wagons, the project is running from July 2020 to December 2022. DAC4EU is a consortium of six public and private freight companies: RCG and DB Cargo (Germany), SBB Cargo (Switzerland), as well as freight wagon owner Ermewa, GATX Rail Europe and VTG.

3. Processing and exploiting data

- The large volumes of data that railways can provide must be accessible for analysis and use by and for operators and customers. This requires intelligent data analysis procedures to be applied, and the most useful results of railway data analysis must be transparently prepared and made available on-line anywhere.

- Track-side and trackside systems provide an enormous amount of data. Hundreds of sensors and control devices on trains, locomotives, buildings and railway systems are recording vast amounts of information, from axle bearing temperature and traction data to door-coupling currents in the wagon, to operating mechanism information and information on bearing and damper defects.

- Through comprehensive cloud-based storage technologies, a large amount of data can be collected and stored long-term and networked via IoT analysis systems, resulting in optimised maintenance and operation.

Big data analytics enables accurate predictive maintenance, based on vehicle and track repair needs, which will significantly reduce unplanned downtime and repair effort.

Today, the latest analytical tools allow for extensive in-depth analysis of digital information, obtaining KPIs for railway operators to optimise the performance of individual vehicles, monitor and optimise the rail network.

4. Running everything in the cloud

- Intelligent open rail infrastructure asset management systems and IOT solutions applied to an infrastructure with a very high potential in the use of sensors should be used.

- The rail infrastructure should be digitally connected, where all possible track-side components should be virtualised, i.e. above track equipment such as signalling, crossing actuators, turnouts and junctions should be digitised and virtualised, e.g. interlockings and CTC (Centralised Traffic Centre) software.

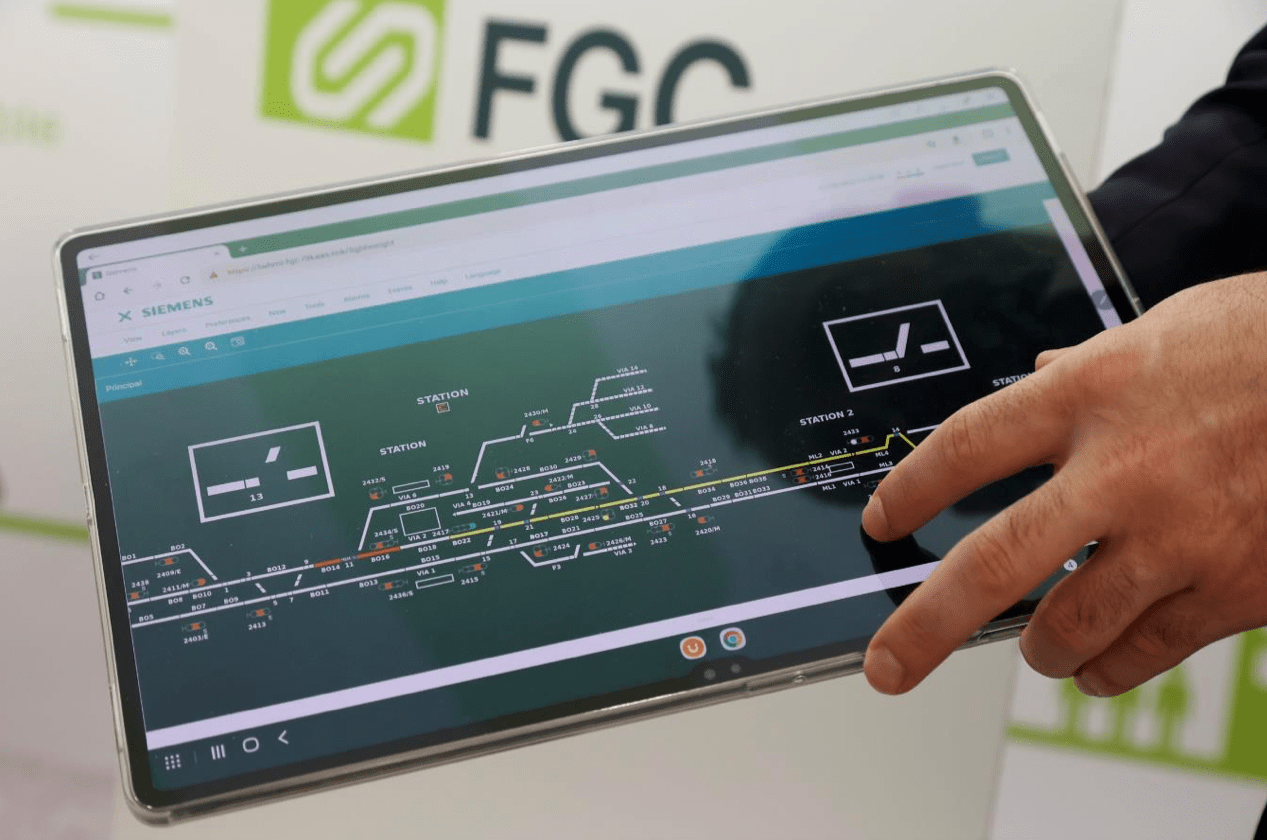

The Ferrocarrils de la Generalitat de Catalunya pilot. FGC is testing the Siemens DS3 system that digitalises interlockings. This concept, which has been designed at the Siemens Mobility R&D&I centre, consists of a digital interlocking that hosts the system that manages the signals and turnouts of each train station in the cloud.

This pilot will increase the capacity of the railway infrastructure by streamlining automatic operations that still take time to communicate from the control centre to the interlocking.

In addition, complementary systems that integrate with the CTC, such as the route planner, driver and operator management, and freight tracking, will be added to the development. The deployment and integration of all these systems is speeded up by being carried out in the cloud.

5. Safety and security as top priorities

Cybersecurity is especially important for networks in railway infrastructures, which are usually protected by firewalls and/or by physical isolation or air gaps.

- Both solutions have their weaknesses. Firewalls are prone to configuration errors and security vulnerabilities. And with air gaps the transmission of data to a recipient outside the network is not possible, and this greatly limits the benefits available from the abundance of data.

- Due to their weaknesses, experts recommend the use of data diodes as an additional security measure for railway IP networks that are particularly at risk, because data diodes only allow data to pass in the predefined direction.The data diode consists of hardware that ensures unidirectional data traffic via fibre-optic transceivers and two servers, called proxies.

In short, the digitalisation train has not yet reached the expected top speed and therefore its entry into its destination station does not seem likely to comply with the timetable set by the EU. There are many intermediate stations to be passed through and various technological challenges to be met. But the inertia of its technological transformation is unavoidable and the locomotive of the modernisation of rail transport will end up being a real bullet train.